Design and Technology

Nuovi Gioielli was founded in 1985 when thanks to our knowledge and passion we made a dream come true. After 35 years this dream keeps on being a reality, which puts together tradition, innovation, research and development.

Our working method is based on the continuous search for new ideas, the update of our technologies and their potential applications.

Technological innovation is a key value, the starting point to develop each new idea and the goal to be reached in each new challenge.

Nuovi Gioielli has invested in both employees and new technologies, aspiring to a unique and original piece of jewellery in combination with an highly qualified staff.

Our company makes jewels for those who are looking for one-of-a-kind product, where skill, design and accuracy are key elements.

OUR STRONG POINTS:

Flexibility: is a vital requirement in order not to get trapped in the economic and systemic complexity in which companies are often involved.

Feasibility: It is not enough to start a new project from an idea. That project have to be achievable i.e. have to succeed in producing a concrete result.

Reaction to change: “It is not the strongest or even the most intelligent individual who survives, but the one who adapts best to change”. How can we keep up to date with this ever-changing world? By knowing the dynamics that characterize a constantly evolving context.

Curiosity: we are inspired by ideas, something that for the moment exists (often in a somewhat vague way) only in our imagination. The ambition to make it happens is the energy that allows us to overcome problems and difficulties and to motivate and encourage our employees. Breaking the rules means defining your own.

Valuing customers: “The only criteria that count in evaluating the quality of the after-sales service are those defined by customers; only customers can judge the quality; all other judgments are essentially irrelevant” (A. Parasuraman – University of Miami). Customer satisfaction is not only guaranteed by the quality of the products and services we offer, but also and above all by the assistance provided throughout the process, whether it is a customer service or an order for a finished product. The quality of the jewel is obviously essential, but it is equally important to know that you can count on industry experts who are able to solve any problems with a well-organized pre and post sales service

| PROCESSING TECHNIQUES | PRODUCTION |

| CASTING LAVORAZIONE CANNA VUOTA COINING – PRINTING SETTING CNC PROCESSING LASER CUTTING INTERNAL DESIGN AND 3D GRAPHIC PROTOTYPING | PRODUCTION PROCESSED CASTING CNC 5-axis LASER for 2D and 3D cutting LASER Welding 3D PRINTING STAMPING AND COINING |

| PROTOTYPING | |

| 3D PRINTER DLP 3D PRINTER LASER MELTING 3D PRINTER STEROLITHOGRAPHY | • without forgetting our many years of experience in MADE IN ITALY craftsmanship |

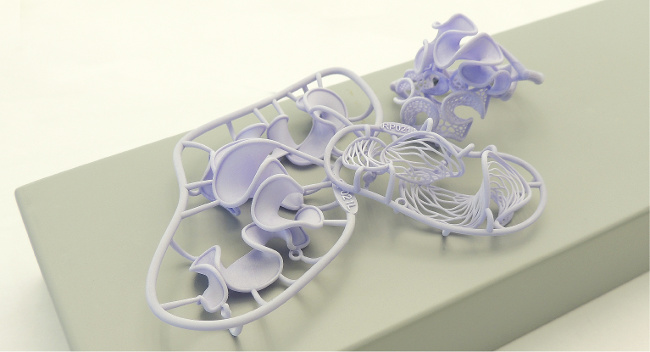

LASER METAL FUSION – Additive Manufacturing

The Laser Metal Fusion is also known as the metal 3D printing and it represents the field of the additive manufacturing industry with the greatest potential for development and growth.

A high-intensity laser creates three-dimensional metal objects, melting metal powders according to a route, which is defined by a CAD drawing. The LMF technology allows to use a wide range of metals, among the most common there are steel, bronze, gold and platinum, used during the research and investigation stage. This research started years ago in cooperation with SISMA Ltd. and it represents our starting point in the field of the additive printing.

From our initial tests we have immediately realized that the LMF is a one-of-a-kind technology.

Thanks to these new technologies, as well as our craftsmanship, our jewels’ design is always both up with the times and original. Moreover, this technique allows us to overcome most of the creative limits caused by traditional manufacturing techniques and the large amount of production steps. Creativity has no limits, it can be expressed by combining aesthetic with mechanical and architectural techniques in a single object, resulting in something truly unique. READ MORE…

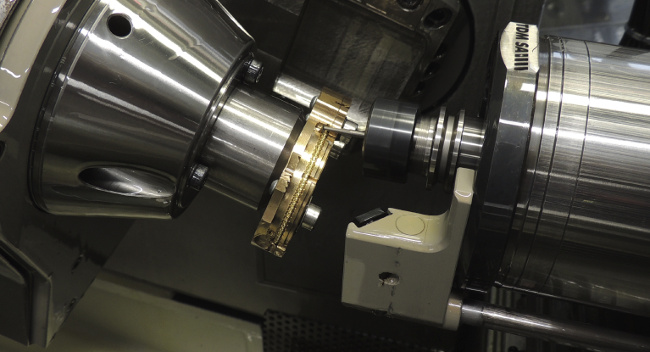

CNC Machine

In the gold industry, the use of CNC machines has increased the accuracy and quality of some components that require particular focus. The functions and movements of a CNC machine are pre-set through specific software. These characteristics make CNC machines perfect for performing high-precision processing, that require a long production time. The main feature of a CNC machine is represented by the degrees of freedom, that is the number of moving axes of the machine. The axes allow the inclination of the tool with respect to the work surface and based on the degrees of freedom, they give less or greater flexibility of movement in the processing.

The 5-axis CNC machine combines the rotation of the tool holder head with the rotation of the component being processed along the other 3 axes. These machines are excellent in terms of movement flexibility and them allow for simultaneous interpolation

CNC processing advantages:

- Processing times reduction;

- Consistent quality and accuracy of components;

- Creation of complex surfaces, such as sharp-edged geometries, which are difficult to realize with traditional processes;

- Stable production efficiency under multiple production conditions.

Customer Service

Our artisans’ skills are constantly updated due to the fact that our company operates in the eyewear, watchmaking, jewellery and design industries. We guarantee strict confidence in all our services and, if required, the exclusivity of the agreed service. Talking about CAD project, 3D modelling, 3D printing, manufacturing: our consultants will suggest you the most suitable solutions for your projects. Designing requires specific skills and knowledge.

Our employees and consultants have extensive experience in several luxury fields and they are at your disposal for:

- Design and execution with CAD software of existing paper drawings;

- STL rapid prototyping (in meltable wax, resin, plastic, noble and non-noble metal);

- Production of rubber moulds (hot runner moulds or cold runner moulds);

- Manual or mechanical processing for the finishing of the articles produced;

- Laser for markings, engravings or micro cuts.

The idea CLEANFLOW

CLEANFLOW is a kit created to support the preparation process of casting cylinders. It’s been developed to improve the flow and the burning phase of the tree material during the burnout cycle.

The principle on which it is based reduces considerably the problems due to slags inside the cylinder and combustion gas bubbles that struggle to exit with the traditional system. Read More…